New slim format Tenger clay pavers

We're excited to present our brand new range of Tenger clay pavers, Staffordshire clay pavers with a contemporary slim format. At 200 x 50x 65mm they are similar in size to dutch pavers, but these are made in our factory in Brierley Hill in the UK and unlike the dutch pavers which tend to have tumbled edges, Ketley Tenger pavers are sharp edged and extremely hardwearing. They are made of the same Etruria marl clay as the rest of the Ketley range (which we extract from our local quarry) and have the same characteristics of extremely low water absorption and very high strength. They are ideal for all domestic and commercial landscaping applications including pathways, driveways, patios and public realm and can withstand both heavy footfall and vehicular traffic. Their dragfaced texture has excellent anti-slip properties.

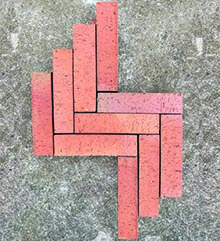

They are available in the 4 traditional, rich, Staffordshire clay colours which will not fade over time, but will last for future generations. They can be used alongside our Classic or patterned paver range to delineate areas of outdoor space and they suit a variety of laying patterns. Here they are shown in a herringbone pattern as 50mm pavers, and also as 65mm pavers in a basket weave, in all 4 colours: Staffordshire Red, Brown Brindle, Staffordshire Blue and Brown Antique

Case Studies

Victorian courtyard garden

Garden designer Victoria Philpott was keen to use materials that would retain the character of her Victorian courtyard whilst also giving it a more contemporary feel. Her front garden features original Staffordshire blue clay pavers and the dark colour complements the limestone walls and oak sleepers within her scheme. Victoria comments, "The new Tenger pavers are a pleasing blend of modern and classic and give the garden a more up-to-date feel. We're really pleased with how well they suit the space and are also glad to be using a British manufacturer." Full details>>

Sculpture garden at RHS Chelsea

Staffordshire red Tenger pavers were laid at RHS Chelsea flower show 2024 for the Tom Hiscocks Sculpture Garden. Their contemporary look suited the context of the modern sculptures and their rich Staffordshire red clay tones brought rich colour to the scheme. Full details>>

Arts & Crafts garden at RHS Tatton Park

A beautiful Arts and Crafts show garden designed by Grant Horticulture featured both brown brindle Tenger pavers and Linium bricks at RHS Tatton Park 2024. 4 brick sculptures were constructed from Ketley's new ultra thin Linium bricks, creating structures reminiscent of the grand decorative chimneys popular during the Arts and Crafts movement. Tenger pavers were also featured within the scheme laid in a traditional basket weave pattern, adding further detail and interest to this Arts and Crafts scheme. The pavers were laid as 65mm pavers rather than 50mm pavers to create the basketweave, and each paver was carefully placed to create the exact colour mix that designer Callum Bain-Mackay felt best complimented his planting scheme. Full details>>

Environmental

Place of Manufacture: Brierley Hill, UK

Environmental Management: 14001 Download Certificate

Quality Management : 9001 Download Certificate

Download the Ketley Quality and Environmental Policy

Life Cycle: BRE Global Certification in accordance with EN 15804:2012 Download Certificate

Energy: Fired in gas kilns to 1130o C

Raw materials: Etruria marl clay from our own quarry in Cannock, 12 miles from our factory, and sand

Lifespan: Clay pavers are long life building products and Ketley's pavers are the toughest and most durable clay pavers you can buy.

Recyclability: Ketley clay pavers can be carefully lifted and reused. They can also be crushed and used as aggregate and/or as an inert bulk fill

Packaging: We keep packaging to a minimum using wooden pallets and we do not shrink wrap our paver packs.

Find out more about Ketley's approach to sustainability

Click for the Brick Development Association infographic on Sustainability of Brick

See below the latest video about Sustainability of Brick from the Brick Development Association

Technical Spec

New Ketley Tenger Pavers Specification Sheet

Performance Standard: BS EN 1344:2013

Ketley Tenger pavers are produced at our works located in the heart of the Black Country where pavers have been made from our own Etruria Marl since Victorian times. Their unrivalled physical properties include their strength, durability and permanence of colour.

Download Specification Sheet

|

Work Size mm |

Units/m2 laid as a 65mm paver (flexible butt jointed with 3mm joint) |

Units/m2 laid as a 50mm paver (flexible butt jointed with 3mm joint) |

No per pallet |

Pattern |

Pack weight

|

|

200x50x65 |

73 |

93 |

640 |

square edged |

832kg |

|

|

|

|

|||

|

Colour |

red, Staffordshire brown brindle, Staffordshire blue, or brown antique |

||||

|

Raw Material |

Etruria marl |

||||

|

Manufacture |

Extruded, Wirecut and fired above 1130 degrees C |

||||

|

Bulk Density |

2,300kg/m3 |

||||

|

Texture |

Dragfaced |

||||

|

Size, Tolerance |

BS EN 1344: 2013 |

||||

|

Size Range |

R1 |

||||

|

Mean Transverse Breaking Load (when laid with 65mm depth) |

T4 |

||||

|

Unpolished Slip/Skid Resistance |

U3 |

||||

|

Abrasion Resistance |

|

||||

|

Freeze/Thaw Resistance |

FP100 |

||||

Fittings

Ketley Brick have a long history producing special bricks and pavers.

Ketley Brick have a long history producing special bricks and pavers.

View our Paver Specials Gallery

Browse our paver specials range online

Our unique plant produces a traditional natural clay colours for both the Paver and Brick ranges. Because our squares, pavers and specials are fired together, our colours are consistent through the range.

Ketley Brick also offers a made to measure service for bespoke requirements, this is covered in the Special Shapes section.

Paver Laying

Paver Laying

Clay pavers should be laid in accordance with BS 7533-3:2005+A1:2009.

For post laying care, download our guide here

Download industry guidance on paver cleaning here

It is useful to plan the layout of pavers before full scale laying begins. It may help to minimize the number of pavers that need to be cut. It will help to identify the likely sand surcharge needed in setting levels. It will also indicate the likely finished appearance and the standard of on-site workmanship.

Clay pavers should be laid by hand, commencing from a straight starting edge on the prepared bedding course. They should be laid slightly open to provide a finished joint width between pavers of approx 2-5mm to permit infill and to minimise damage in compaction and subsequent use. Failure to do this may result in chipping of the clay pavers. If deviation from the bond pattern occurs, the pavers can be adjusted to open the Joints to about 5mm. This process is known as gapping. A small percentage outside this figure will not affect paver performance.

Clay pavers should be laid by hand, commencing from a straight starting edge on the prepared bedding course. They should be laid slightly open to provide a finished joint width between pavers of approx 2-5mm to permit infill and to minimise damage in compaction and subsequent use. Failure to do this may result in chipping of the clay pavers. If deviation from the bond pattern occurs, the pavers can be adjusted to open the Joints to about 5mm. This process is known as gapping. A small percentage outside this figure will not affect paver performance.

When a 90° herringbone bond pattern is used, a string line should be set up at right angles to the starting edge, and a "nose" of paving can then be advanced along it. When laying 45° herringbone pattern the laying face should develop parallel to the starting edge.

-

Pavers should be selected from three or more packs to ensure a thorough mix. If stocks of new pavers have to be laid on new work, they should be stacked about one metre back from the leading laid edge.

Pavers should be selected from three or more packs to ensure a thorough mix. If stocks of new pavers have to be laid on new work, they should be stacked about one metre back from the leading laid edge. -

As far as possible whole pavers should be used. Pieces of less than 1/3rd of a full paver should be avoided. Various items in the Ketley range of paver fittings overcome this problem. Infilling of boundaries and obstructions should be completed before vibration commences. Paver cutting should be carried out by a disc cutter, not by the use of a splitting machine or hammer and chisel.

It is important to check the pattern of pavers against string lines as work progresses and adjust as necessary.

Once a sufficient area of clay pavers has been placed, approximately 40m2 on larger sites, fine dry sand should be brushed into the joints.

After brushing into the joints, surplus sand should be brushed away before compaction begins. Pavers should then be compacted into position by two or three passes of a vibrating plate compactor fitted with a neoprene pad. As recommended in BS7533-3:2005, the plate area should be at least 0.20m2. it should transmit an effective force of 50-75 :kn/m2 at a vibration frequency of between 60-1OOHz. Compaction should not be performed closer than one metre from any unrestrained edge.

Further sand should then be applied and the procedure repeated. After final compaction 1-2mm of sand can be spread over the paved area to promote joint filling and to fill any voids which may develop.

Further sand should then be applied and the procedure repeated. After final compaction 1-2mm of sand can be spread over the paved area to promote joint filling and to fill any voids which may develop.

Commencement of use of the pavement may need to be delayed if the bedding course is saturated following heavy rain. During the early life of the pavement there is likely to be some settlement of sand within the joints. Therefore the site should be monitored and arrangements made for further sand to be brushed in, to top up the joints.

Instructions on how to lay for rigid construction can be found in our Clay Pavers and Fittings brochure (available here for download)

Cleaning

Paver Cleaning

Paved areas should be swept with a stiff brush on a regular basis, to remove dust and detritus that tends to accumulate, especially in sheltered corners, and around drains.

The paving should be inspected on a quarterly basis, looking for loose, damaged or stained paving, and checking that the joints are filled. Vacuum road sweepers should not be used during the early life of the pavement as they will remove the jointing sand. Other causes for loss of jointing sand include, erosion by exceptional surface water flow, the effects of high-powered engines or power-washers, action of ants or insects and loss due to movement of the paving.

In situations where an excessive amount of grime and dirt has built up, occasional steam cleaning should be carried out. Jointing sand levels should be checked after this operation and replaced as required.

Pavements in damp areas such as beneath trees and in permanent shade may develop unwanted weed or moss growth. Regular brushing will disrupt emerging weeds, a proprietary weed killer should be used which will have no detrimental effect on the pavers for more stubborn weeds. It is always wise to test the product to be used in a small area first.